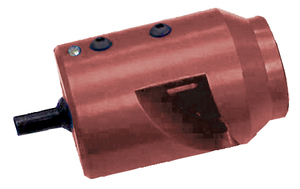

AVA7RK-50

AVA7RK-50, HELIAX® Andrew Virtual Air™ Coaxial Cable, corrugated copper, 1-5/8 in, black non-halogenated, fire retardant polyolefin jacket Cca-s2, d2, a1 (CPR testing is conducted annually please reference the website for latest classification)

Specifications

Product Classification

| Product Type | Coaxial wireless cable |

| Product Brand | HELIAX® |

| Product Series | AVA7-50 |

| Ordering Note | CommScope® standard product in Asia Pacific | CommScope® standard product in Europe, the Middle East, and Africa |

General Specifications

| Product Number | 520096802/00 | SZ520096802/00 |

| Flexibility | Standard |

| Jacket Color | Black |

| Performance Note | Attenuation values typical, guaranteed within 5% |

Dimensions

| Diameter Over Dielectric | 44.45 mm | 1.75 in |

| Diameter Over Jacket | 51.054 mm | 2.01 in |

| Inner Conductor OD | 18.161 mm | 0.715 in |

| Outer Conductor OD | 46.355 mm | 1.825 in |

| Nominal Size | 1-5/8 in |

Electrical Specifications

| Cable Impedance | 50 ohm ±1 ohm |

| Capacitance | 72.2 pF/m | 22.007 pF/ft |

| dc Resistance, Inner Conductor | 1.435 ohms/km | 0.437 ohms/kft |

| dc Resistance, Outer Conductor | 0.525 ohms/km | 0.16 ohms/kft |

| dc Test Voltage | 15000 V |

| Inductance | 0.187 µH/m | 0.057 µH/ft |

| Insulation Resistance | 100000 MOhms-km |

| Jacket Spark Test Voltage (rms) | 8000 V |

| Operating Frequency Band | 1 – 2700 MHz |

| Peak Power | 302 kW |

| Velocity | 92 % |

Attenuation

Attenuation

| Frequency | Attenuation (dB/100 m) | Attenuation (dB/100 ft) | Average Power (kW) |

| 1.0 MHz | 0.062 | 0.019 | 117.56 |

| 1.5 MHz | 0.076 | 0.023 | 95.88 |

| 2.0 MHz | 0.088 | 0.027 | 82.96 |

| 10.0 MHz | 0.197 | 0.060 | 36.78 |

| 20.0 MHz | 0.281 | 0.086 | 25.84 |

| 30.0 MHz | 0.346 | 0.105 | 21.00 |

| 50.0 MHz | 0.450 | 0.137 | 16.14 |

| 85.0 MHz | 0.593 | 0.181 | 12.25 |

| 88.0 MHz | 0.603 | 0.184 | 12.03 |

| 100.0 MHz | 0.645 | 0.197 | 11.26 |

| 108.0 MHz | 0.672 | 0.205 | 10.81 |

| 150.0 MHz | 0.798 | 0.243 | 9.09 |

| 174.0 MHz | 0.864 | 0.263 | 8.41 |

| 200.0 MHz | 0.930 | 0.284 | 7.81 |

| 204.0 MHz | 0.940 | 0.287 | 7.72 |

| 300.0 MHz | 1.156 | 0.352 | 6.28 |

| 400.0 MHz | 1.351 | 0.412 | 5.37 |

| 450.0 MHz | 1.441 | 0.439 | 5.04 |

| 460.0 MHz | 1.459 | 0.445 | 4.98 |

| 500.0 MHz | 1.527 | 0.465 | 4.76 |

| 512.0 MHz | 1.547 | 0.471 | 4.69 |

| 600.0 MHz | 1.689 | 0.515 | 4.30 |

| 700.0 MHz | 1.840 | 0.561 | 3.95 |

| 800.0 MHz | 1.982 | 0.604 | 3.66 |

| 824.0 MHz | 2.016 | 0.614 | 3.60 |

| 894.0 MHz | 2.110 | 0.643 | 3.44 |

| 960.0 MHz | 2.197 | 0.670 | 3.30 |

| 1000.0 MHz | 2.249 | 0.685 | 3.23 |

| 1218.0 MHz | 2.517 | 0.767 | 2.89 |

| 1250.0 MHz | 2.554 | 0.779 | 2.84 |

| 1500.0 MHz | 2.838 | 0.865 | 2.56 |

| 1700.0 MHz | 3.053 | 0.930 | 2.38 |

| 1794.0 MHz | 3.151 | 0.960 | 2.30 |

| 1800.0 MHz | 3.157 | 0.962 | 2.30 |

| 2000.0 MHz | 3.359 | 1.024 | 2.16 |

| 2100.0 MHz | 3.457 | 1.054 | 2.10 |

| 2200.0 MHz | 3.554 | 1.083 | 2.04 |

| 2300.0 MHz | 3.649 | 1.112 | 1.99 |

| 2500.0 MHz | 3.836 | 1.169 | 1.89 |

| 2700.0 MHz | 4.017 | 1.224 | 1.81 |

Return Loss/VSWR

| Frequency Band | VSWR | Return Loss (dB) |

| 680–800 MHz | 1.130 | 24.30 |

| 806–960 MHz | 1.130 | 24.30 |

| 1700–2170 MHz | 1.130 | 24.30 |

Material Specifications

| Dielectric Material | Foam PE |

| Jacket Material | Non-halogenated, fire retardant polyolefin |

| Inner Conductor Material | Corrugated copper tube |

| Outer Conductor Material | Corrugated copper |

Mechanical Specifications

| Minimum Bend Radius, multiple Bends | 381 mm | 15 in |

| Minimum Bend Radius, Single Bend | 203.2 mm | 8 in |

| Number of Bends, minimum | 15 |

| Number of Bends, typical | 50 |

| Tensile Strength | 181 kg | 399.036 lb |

| Bending Moment | 47.5 N-m | 420.41 in lb |

| Flat Plate Crush Strength | 1.6 kg/mm | 89.596 lb/in |

Environmental Specifications

| Installation temperature | -40 °C to +60 °C (-40 °F to +140 °F) |

| Operating Temperature | -40 °C to +60 °C (-40 °F to +140 °F) |

| Storage Temperature | -40 °C to +60 °C (-40 °F to +140 °F) |

| Attenuation, Ambient Temperature | 20 °C | 68 °F |

| Average Power, Ambient Temperature | 40 °C | 104 °F |

| Average Power, Inner Conductor Temperature | 100 °C | 212 °F |

| EN50575 CPR Cable EuroClass Fire Performance | Cca |

| EN50575 CPR Cable EuroClass Smoke Rating | s2 |

| EN50575 CPR Cable EuroClass Droplets Rating | d2 |

| EN50575 CPR Cable EuroClass Acidity Rating | a1 |

| Fire Retardancy Test Method | IEC 60332-1-2 | NFPA 130-2010 | UL 1666/CATVR |

| Smoke Index Test Method | IEC 61034 |

| Toxicity Index Test Method | IEC 60754-1 | IEC 60754-2 |

Packaging and Weights

| Cable weight | 1.2 kg/m | 0.806 lb/ft |

Regulatory Compliance/Certifications

| Agency | Classification |

|

CENELEC

|

EN 50575 compliant, Declaration of Performance (DoP) available |

| ISO 9001:2015 | Designed, manufactured and/or distributed under this quality management system |

| ROHS | Compliant |

|

UL/ETL Certification

|

CATVR |

|

CHINA-ROHS

|

Below maximum concentration value |

| REACH-SVHC | Compliant as per SVHC revision on www.commscope.com/ProductCompliance |

| UK-ROHS | Compliant |

Product Classification

| Product Type | Coaxial wireless cable |

| Product Brand | HELIAX® |

| Product Series | AVA7-50 |

| Ordering Note | CommScope® standard product in Asia Pacific | CommScope® standard product in Europe, the Middle East, and Africa |

General Specifications

| Product Number | 520096802/00 | SZ520096802/00 |

| Flexibility | Standard |

| Jacket Color | Black |

| Performance Note | Attenuation values typical, guaranteed within 5% |

Dimensions

| Diameter Over Dielectric | 44.45 mm | 1.75 in |

| Diameter Over Jacket | 51.054 mm | 2.01 in |

| Inner Conductor OD | 18.161 mm | 0.715 in |

| Outer Conductor OD | 46.355 mm | 1.825 in |

| Nominal Size | 1-5/8 in |

Electrical Specifications

| Cable Impedance | 50 ohm ±1 ohm |

| Capacitance | 72.2 pF/m | 22.007 pF/ft |

| dc Resistance, Inner Conductor | 1.435 ohms/km | 0.437 ohms/kft |

| dc Resistance, Outer Conductor | 0.525 ohms/km | 0.16 ohms/kft |

| dc Test Voltage | 15000 V |

| Inductance | 0.187 µH/m | 0.057 µH/ft |

| Insulation Resistance | 100000 MOhms-km |

| Jacket Spark Test Voltage (rms) | 8000 V |

| Operating Frequency Band | 1 – 2700 MHz |

| Peak Power | 302 kW |

| Velocity | 92 % |

Attenuation

Attenuation

| Frequency | Attenuation (dB/100 m) | Attenuation (dB/100 ft) | Average Power (kW) |

| 1.0 MHz | 0.062 | 0.019 | 117.56 |

| 1.5 MHz | 0.076 | 0.023 | 95.88 |

| 2.0 MHz | 0.088 | 0.027 | 82.96 |

| 10.0 MHz | 0.197 | 0.060 | 36.78 |

| 20.0 MHz | 0.281 | 0.086 | 25.84 |

| 30.0 MHz | 0.346 | 0.105 | 21.00 |

| 50.0 MHz | 0.450 | 0.137 | 16.14 |

| 85.0 MHz | 0.593 | 0.181 | 12.25 |

| 88.0 MHz | 0.603 | 0.184 | 12.03 |

| 100.0 MHz | 0.645 | 0.197 | 11.26 |

| 108.0 MHz | 0.672 | 0.205 | 10.81 |

| 150.0 MHz | 0.798 | 0.243 | 9.09 |

| 174.0 MHz | 0.864 | 0.263 | 8.41 |

| 200.0 MHz | 0.930 | 0.284 | 7.81 |

| 204.0 MHz | 0.940 | 0.287 | 7.72 |

| 300.0 MHz | 1.156 | 0.352 | 6.28 |

| 400.0 MHz | 1.351 | 0.412 | 5.37 |

| 450.0 MHz | 1.441 | 0.439 | 5.04 |

| 460.0 MHz | 1.459 | 0.445 | 4.98 |

| 500.0 MHz | 1.527 | 0.465 | 4.76 |

| 512.0 MHz | 1.547 | 0.471 | 4.69 |

| 600.0 MHz | 1.689 | 0.515 | 4.30 |

| 700.0 MHz | 1.840 | 0.561 | 3.95 |

| 800.0 MHz | 1.982 | 0.604 | 3.66 |

| 824.0 MHz | 2.016 | 0.614 | 3.60 |

| 894.0 MHz | 2.110 | 0.643 | 3.44 |

| 960.0 MHz | 2.197 | 0.670 | 3.30 |

| 1000.0 MHz | 2.249 | 0.685 | 3.23 |

| 1218.0 MHz | 2.517 | 0.767 | 2.89 |

| 1250.0 MHz | 2.554 | 0.779 | 2.84 |

| 1500.0 MHz | 2.838 | 0.865 | 2.56 |

| 1700.0 MHz | 3.053 | 0.930 | 2.38 |

| 1794.0 MHz | 3.151 | 0.960 | 2.30 |

| 1800.0 MHz | 3.157 | 0.962 | 2.30 |

| 2000.0 MHz | 3.359 | 1.024 | 2.16 |

| 2100.0 MHz | 3.457 | 1.054 | 2.10 |

| 2200.0 MHz | 3.554 | 1.083 | 2.04 |

| 2300.0 MHz | 3.649 | 1.112 | 1.99 |

| 2500.0 MHz | 3.836 | 1.169 | 1.89 |

| 2700.0 MHz | 4.017 | 1.224 | 1.81 |

Return Loss/VSWR

| Frequency Band | VSWR | Return Loss (dB) |

| 680–800 MHz | 1.130 | 24.30 |

| 806–960 MHz | 1.130 | 24.30 |

| 1700–2170 MHz | 1.130 | 24.30 |

Material Specifications

| Dielectric Material | Foam PE |

| Jacket Material | Non-halogenated, fire retardant polyolefin |

| Inner Conductor Material | Corrugated copper tube |

| Outer Conductor Material | Corrugated copper |

Mechanical Specifications

| Minimum Bend Radius, multiple Bends | 381 mm | 15 in |

| Minimum Bend Radius, Single Bend | 203.2 mm | 8 in |

| Number of Bends, minimum | 15 |

| Number of Bends, typical | 50 |

| Tensile Strength | 181 kg | 399.036 lb |

| Bending Moment | 47.5 N-m | 420.41 in lb |

| Flat Plate Crush Strength | 1.6 kg/mm | 89.596 lb/in |

Environmental Specifications

| Installation temperature | -40 °C to +60 °C (-40 °F to +140 °F) |

| Operating Temperature | -40 °C to +60 °C (-40 °F to +140 °F) |

| Storage Temperature | -40 °C to +60 °C (-40 °F to +140 °F) |

| Attenuation, Ambient Temperature | 20 °C | 68 °F |

| Average Power, Ambient Temperature | 40 °C | 104 °F |

| Average Power, Inner Conductor Temperature | 100 °C | 212 °F |

| EN50575 CPR Cable EuroClass Fire Performance | Cca |

| EN50575 CPR Cable EuroClass Smoke Rating | s2 |

| EN50575 CPR Cable EuroClass Droplets Rating | d2 |

| EN50575 CPR Cable EuroClass Acidity Rating | a1 |

| Fire Retardancy Test Method | IEC 60332-1-2 | NFPA 130-2010 | UL 1666/CATVR |

| Smoke Index Test Method | IEC 61034 |

| Toxicity Index Test Method | IEC 60754-1 | IEC 60754-2 |

Packaging and Weights

| Cable weight | 1.2 kg/m | 0.806 lb/ft |

Regulatory Compliance/Certifications

| Agency | Classification |

|

CENELEC

|

EN 50575 compliant, Declaration of Performance (DoP) available |

| ISO 9001:2015 | Designed, manufactured and/or distributed under this quality management system |

| ROHS | Compliant |

|

UL/ETL Certification

|

CATVR |

|

CHINA-ROHS

|

Below maximum concentration value |

| REACH-SVHC | Compliant as per SVHC revision on www.commscope.com/ProductCompliance |

| UK-ROHS | Compliant |

Documentation & Downloads

Certificate of Compliance

Product Specification

Technical Publication

Warranty

Certificate of Compliance

Product Compliance Documentation

Product Specification

Technical Publication

Warranty

Other Ways to Browse