810009731/DB | B-288-LN-8W-F24NS/17G/200

Base Product: B-LN

- Available in:

- Asia

- Australia/New Zealand

- EMEA

- Latin America

- North America

Fiber OSP cable, Zero Water Peak® Blown Micro Single Jacket All-Dielectric Outdoor Stranded Loose Tube 200um Fiber Arid-Core® Construction, 288 fiber, Singlemode G.657.A1, Gel-filled, Feet jacket marking, Black jacket color

Build America Buy America (BABA)*

Rely on CommScope for Broadband Equity Access and Development (BEAD) Program and other government funded projects

Features and Benefits

- *Product complies with the Build America, Buy America Act (BABAA) requirements of the Infrastructure Investment and Jobs Act of 2021 (Pub. L. 117- 58, §§ 70901-70953), or is the subject of a waiver approved by the Secretary of Commerce or designee. Compliance requirements and waiver applicability vary based on government funding program. Check the laws and regulations for your specific program.

Specifications

Product Classification

| Regional Availability | Asia | Australia/New Zealand | EMEA | Latin America | North America |

| Portfolio | CommScope® |

| Product Type | Fiber OSP cable |

| Product Series | B-LN |

| Government Funding | Build America Buy America (BABA) compliant* |

General Specifications

| Cable Type | Stranded loose tube |

| Construction Type | Non-armored |

| Subunit Type | Gel-filled |

| Filler, quantity | 0 |

| Jacket Color | Black |

| Jacket Marking | Feet |

| Jacket Marking Method | Laser |

| Jacket Marking Text | COMMSCOPE GB (YYYY) 810009731/DB 288 X G657A1 200um (Serial number) (feet) FT |

| Subunit, quantity | 12 |

| Fibers per Subunit, quantity | 24 |

| Total Fiber Count | 288 |

Dimensions

| Buffer Tube/Subunit Diameter | 1.7 mm | 0.067 in |

| Diameter Over Jacket | 9.5 mm | 0.374 in |

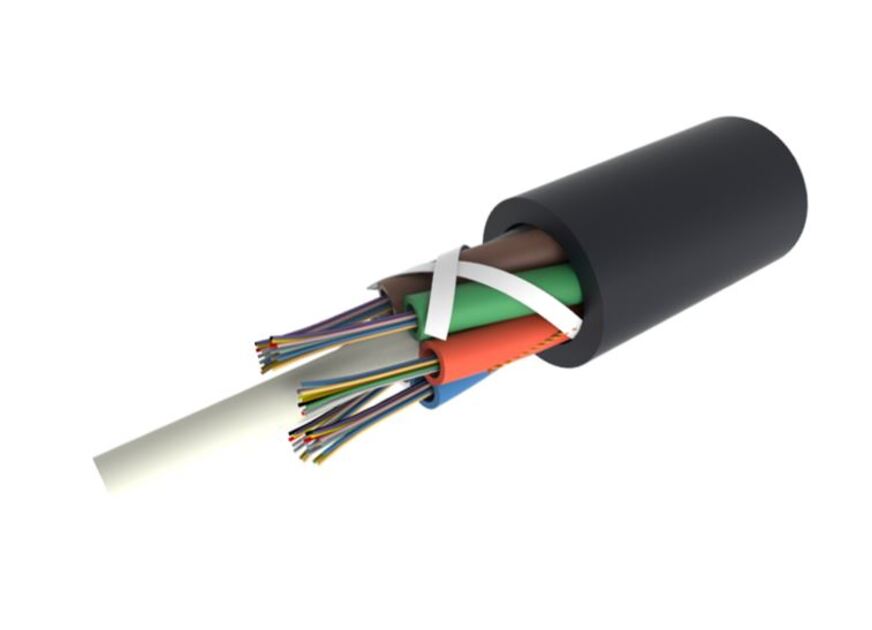

Representative Image

| Click on image to enlarge. |

Material Specifications

| Jacket Material | High density polyethylene (HDPE) |

Mechanical Specifications

| Minimum Bend Radius, loaded | 143 mm | 5.630 in |

| Minimum Bend Radius, unloaded | 95 mm | 3.740 in |

| Tensile Load, long term, maximum | 335 N | 75.311 lbf |

| Tensile Load, short term, maximum | 1000 N | 224.809 lbf |

| Compression | 10 N/mm | 57.101 lb/in |

| Compression Test Method | FOTP-41 | IEC 60794-1 E3 |

| Flex | 25 cycles |

| Flex Test Method | FOTP-104 | IEC 60794-1 E6 |

| Impact | 0.3 N-m | 2.655 in lb |

| Impact Test Method | FOTP-25 | IEC 60794-1 E4 |

| Strain | See long and short term tensile loads |

| Strain Test Method | FOTP-33 | IEC 60794-1 E1 |

| Twist | 10 cycles |

| Twist Test Method | FOTP-85 | IEC 60794-1 E7 |

| Vertical Rise, maximum | 769 m | 2522.966 ft |

Optical Specifications

| Fiber Type | G.657.A1, TeraSPEED® |

Environmental Specifications

| Installation temperature | -30 °C to +70 °C (-22 °F to +158 °F) |

| Operating Temperature | -40 °C to +70 °C (-40 °F to +158 °F) |

| Storage Temperature | -40 °C to +70 °C (-40 °F to +158 °F) |

| Cable Qualification Standards | IEC 60794-5-10 |

| Environmental Space | Air-blown, microduct |

| Jacket UV Resistance | UV stabilized |

| Water Penetration | 24 h |

| Water Penetration Test Method | FOTP-82 | IEC 60794-1 F5 |

Environmental Test Specifications

| Cable Freeze | -2 °C | 28.4 °F |

| Cable Freeze Test Method | FOTP-98 | IEC 60794-1 F15 |

| Drip | 70 °C | 158 °F |

| Drip Test Method | FOTP-81 | IEC 60794-1 E14 |

| Heat Age | -40 °C to +85 °C (-40 °F to +185 °F) |

| Heat Age Test Method | IEC 60794-1 F9 |

| Low High Bend | -30 °C to +60 °C (-22 °F to +140 °F) |

| Low High Bend Test Method | FOTP-37 | IEC 60794-1 E11 |

| Temperature Cycle | -40 °C to +70 °C (-40 °F to +158 °F) |

| Temperature Cycle Test Method | FOTP-3 | IEC 60794-1 F1 |

Packaging and Weights

| Cable weight | 77.5 kg/km | 52.078 lb/kft |

Product Classification

| Regional Availability | Asia | Australia/New Zealand | EMEA | Latin America | North America |

| Portfolio | CommScope® |

| Product Type | Fiber OSP cable |

| Product Series | B-LN |

| Government Funding | Build America Buy America (BABA) compliant* |

General Specifications

| Cable Type | Stranded loose tube |

| Construction Type | Non-armored |

| Subunit Type | Gel-filled |

| Filler, quantity | 0 |

| Jacket Color | Black |

| Jacket Marking | Feet |

| Jacket Marking Method | Laser |

| Jacket Marking Text | COMMSCOPE GB (YYYY) 810009731/DB 288 X G657A1 200um (Serial number) (feet) FT |

| Subunit, quantity | 12 |

| Fibers per Subunit, quantity | 24 |

| Total Fiber Count | 288 |

Dimensions

| Buffer Tube/Subunit Diameter | 1.7 mm | 0.067 in |

| Diameter Over Jacket | 9.5 mm | 0.374 in |

Material Specifications

| Jacket Material | High density polyethylene (HDPE) |

Mechanical Specifications

| Minimum Bend Radius, loaded | 143 mm | 5.630 in |

| Minimum Bend Radius, unloaded | 95 mm | 3.740 in |

| Tensile Load, long term, maximum | 335 N | 75.311 lbf |

| Tensile Load, short term, maximum | 1000 N | 224.809 lbf |

| Compression | 10 N/mm | 57.101 lb/in |

| Compression Test Method | FOTP-41 | IEC 60794-1 E3 |

| Flex | 25 cycles |

| Flex Test Method | FOTP-104 | IEC 60794-1 E6 |

| Impact | 0.3 N-m | 2.655 in lb |

| Impact Test Method | FOTP-25 | IEC 60794-1 E4 |

| Strain | See long and short term tensile loads |

| Strain Test Method | FOTP-33 | IEC 60794-1 E1 |

| Twist | 10 cycles |

| Twist Test Method | FOTP-85 | IEC 60794-1 E7 |

| Vertical Rise, maximum | 769 m | 2522.966 ft |

Optical Specifications

| Fiber Type | G.657.A1, TeraSPEED® |

Environmental Specifications

| Installation temperature | -30 °C to +70 °C (-22 °F to +158 °F) |

| Operating Temperature | -40 °C to +70 °C (-40 °F to +158 °F) |

| Storage Temperature | -40 °C to +70 °C (-40 °F to +158 °F) |

| Cable Qualification Standards | IEC 60794-5-10 |

| Environmental Space | Air-blown, microduct |

| Jacket UV Resistance | UV stabilized |

| Water Penetration | 24 h |

| Water Penetration Test Method | FOTP-82 | IEC 60794-1 F5 |

Environmental Test Specifications

| Cable Freeze | -2 °C | 28.4 °F |

| Cable Freeze Test Method | FOTP-98 | IEC 60794-1 F15 |

| Drip | 70 °C | 158 °F |

| Drip Test Method | FOTP-81 | IEC 60794-1 E14 |

| Heat Age | -40 °C to +85 °C (-40 °F to +185 °F) |

| Heat Age Test Method | IEC 60794-1 F9 |

| Low High Bend | -30 °C to +60 °C (-22 °F to +140 °F) |

| Low High Bend Test Method | FOTP-37 | IEC 60794-1 E11 |

| Temperature Cycle | -40 °C to +70 °C (-40 °F to +158 °F) |

| Temperature Cycle Test Method | FOTP-3 | IEC 60794-1 F1 |

Packaging and Weights

| Cable weight | 77.5 kg/km | 52.078 lb/kft |

| Click on image to enlarge. |

Documentation & Downloads

Product Specification

Warranty

Product Compliance Documentation

Product Specification

Warranty

Other Ways to Browse