760096461 | Z-024-DN-CM-F12BK/8W012/5L012/D

Base Product: Z-DN

- Available in:

- Asia

- Australia/New Zealand

- EMEA

- Latin America

- North America

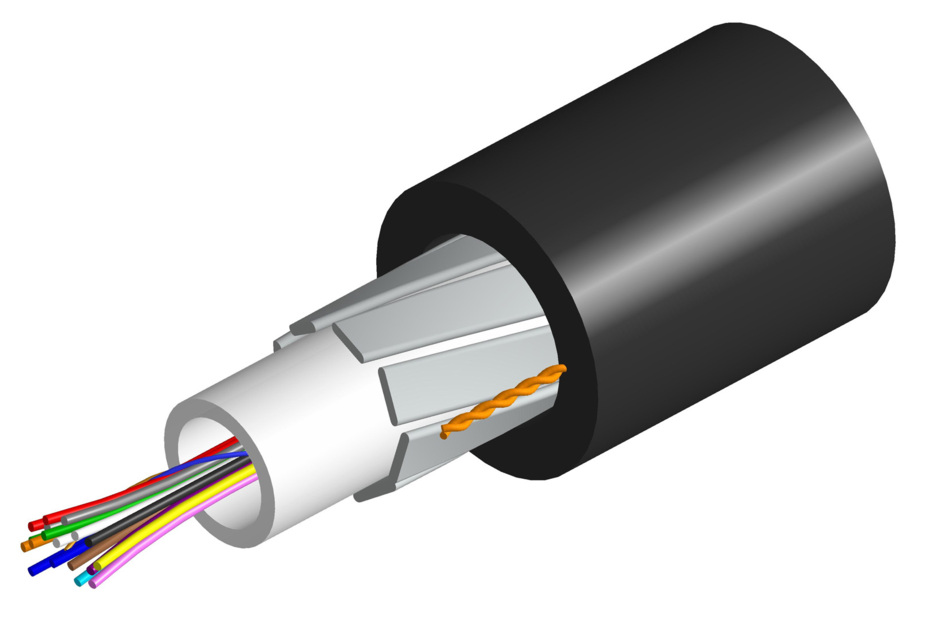

Fiber Indoor/Outdoor Drop Cable, TeraSPEED®, Low Smoke Zero Halogen, 24 fiber, Single Jacket All-Dielectric Arid-Core, Gel-filled, Singlemode + Multimode OM3, Feet jacket marking, Black jacket color, Dca flame rating

Specifications

Product Classification

| Regional Availability | Asia | Australia/New Zealand | EMEA | Latin America | North America |

| Portfolio | CommScope® |

| Product Type | Fiber drop cable |

| Product Series | Z-DN |

General Specifications

| Bundle, quantity | 2 |

| Cable Type | Riser rated low smoke |

| Construction Type | Non-armored |

| Subunit Type | Gel-filled |

| Jacket Color | Black |

| Jacket Marking | Feet |

| Subunit, quantity | 1 |

| Composite Fiber Count | 12 + 12 |

| Total Fiber Count | 24 |

Dimensions

| Buffer Tube/Subunit Diameter | 4 mm | 0.157 in |

| Diameter Over Jacket | 8.3 mm | 0.327 in |

Representative Image

| Click on image to enlarge. |

Material Specifications

| Jacket Material | Low Smoke Zero Halogen (LSZH) |

Mechanical Specifications

| Minimum Bend Radius, loaded | 125 mm | 4.921 in |

| Minimum Bend Radius, unloaded | 83 mm | 3.268 in |

| Tensile Load, long term, maximum | 400 N | 89.924 lbf |

| Tensile Load, short term, maximum | 1334 N | 299.895 lbf |

| Compression | 10 N/mm | 57.101 lb/in |

| Compression Test Method | FOTP-41 | IEC 60794-1 E3 |

| Flex | 35 cycles |

| Flex Test Method | FOTP-104 | IEC 60794-1 E6 |

| Impact | 2.94 N-m | 26.021 in lb |

| Impact Test Method | FOTP-25 | IEC 60794-1 E4 |

| Strain | See long and short term tensile loads |

| Strain Test Method | FOTP-33 | IEC 60794-1 E1 |

| Twist | 10 cycles |

| Twist Test Method | FOTP-85 | IEC 60794-1 E7 |

| Vertical Rise, maximum | 572 m | 1876.64 ft |

Optical Specifications

| Fiber Type | Composite MM/SM | G.652.D and G.657.A1, TeraSPEED® | OM3, LazrSPEED® 300 |

Environmental Specifications

| Installation temperature | -20 °C to +60 °C (-4 °F to +140 °F) |

| Operating Temperature | -20 °C to +70 °C (-4 °F to +158 °F) |

| Storage Temperature | -20 °C to +75 °C (-4 °F to +167 °F) |

| Cable Qualification Standards | ANSI/ICEA S-110-717 |

| EN50575 CPR Cable EuroClass Fire Performance | Dca |

| EN50575 CPR Cable EuroClass Smoke Rating | s2 |

| EN50575 CPR Cable EuroClass Droplets Rating | d1 |

| EN50575 CPR Cable EuroClass Acidity Rating | a1 |

| Environmental Space | Aerial, lashed | Buried | Low Smoke Zero Halogen (LSZH) | Riser |

| Flame Test Method | IEC 60332-3 | IEC 60754-2 | IEC 61034-2 | UL 1666 | UL 1685 |

| Jacket UV Resistance | UV stabilized |

| Water Penetration | 24 h |

| Water Penetration Test Method | FOTP-82 | IEC 60794-1 F5 |

Environmental Test Specifications

| Cable Freeze | -2 °C | 28.4 °F |

| Cable Freeze Test Method | FOTP-98 | IEC 60794-1 F15 |

| Drip | 70 °C | 158 °F |

| Drip Test Method | FOTP-81 | IEC 60794-1 E14 |

| Heat Age Test Method | IEC 60794-1 F9 |

| Low High Bend | -20 °C to +60 °C (-4 °F to +140 °F) |

| Low High Bend Test Method | FOTP-37 | IEC 60794-1 E11 |

| Temperature Cycle | -20 °C to +70 °C (-4 °F to +158 °F) |

| Temperature Cycle Test Method | FOTP-3 | IEC 60794-1 F1 |

Packaging and Weights

| Cable weight | 72 kg/km | 48.382 lb/kft |

Regulatory Compliance/Certifications

| Agency | Classification |

|

CENELEC

|

EN 50575 compliant, Declaration of Performance (DoP) available |

| ISO 9001:2015 | Designed, manufactured and/or distributed under this quality management system |

Product Classification

| Regional Availability | Asia | Australia/New Zealand | EMEA | Latin America | North America |

| Portfolio | CommScope® |

| Product Type | Fiber drop cable |

| Product Series | Z-DN |

General Specifications

| Bundle, quantity | 2 |

| Cable Type | Riser rated low smoke |

| Construction Type | Non-armored |

| Subunit Type | Gel-filled |

| Jacket Color | Black |

| Jacket Marking | Feet |

| Subunit, quantity | 1 |

| Composite Fiber Count | 12 + 12 |

| Total Fiber Count | 24 |

Dimensions

| Buffer Tube/Subunit Diameter | 4 mm | 0.157 in |

| Diameter Over Jacket | 8.3 mm | 0.327 in |

Material Specifications

| Jacket Material | Low Smoke Zero Halogen (LSZH) |

Mechanical Specifications

| Minimum Bend Radius, loaded | 125 mm | 4.921 in |

| Minimum Bend Radius, unloaded | 83 mm | 3.268 in |

| Tensile Load, long term, maximum | 400 N | 89.924 lbf |

| Tensile Load, short term, maximum | 1334 N | 299.895 lbf |

| Compression | 10 N/mm | 57.101 lb/in |

| Compression Test Method | FOTP-41 | IEC 60794-1 E3 |

| Flex | 35 cycles |

| Flex Test Method | FOTP-104 | IEC 60794-1 E6 |

| Impact | 2.94 N-m | 26.021 in lb |

| Impact Test Method | FOTP-25 | IEC 60794-1 E4 |

| Strain | See long and short term tensile loads |

| Strain Test Method | FOTP-33 | IEC 60794-1 E1 |

| Twist | 10 cycles |

| Twist Test Method | FOTP-85 | IEC 60794-1 E7 |

| Vertical Rise, maximum | 572 m | 1876.64 ft |

Optical Specifications

| Fiber Type | Composite MM/SM | G.652.D and G.657.A1, TeraSPEED® | OM3, LazrSPEED® 300 |

Environmental Specifications

| Installation temperature | -20 °C to +60 °C (-4 °F to +140 °F) |

| Operating Temperature | -20 °C to +70 °C (-4 °F to +158 °F) |

| Storage Temperature | -20 °C to +75 °C (-4 °F to +167 °F) |

| Cable Qualification Standards | ANSI/ICEA S-110-717 |

| EN50575 CPR Cable EuroClass Fire Performance | Dca |

| EN50575 CPR Cable EuroClass Smoke Rating | s2 |

| EN50575 CPR Cable EuroClass Droplets Rating | d1 |

| EN50575 CPR Cable EuroClass Acidity Rating | a1 |

| Environmental Space | Aerial, lashed | Buried | Low Smoke Zero Halogen (LSZH) | Riser |

| Flame Test Method | IEC 60332-3 | IEC 60754-2 | IEC 61034-2 | UL 1666 | UL 1685 |

| Jacket UV Resistance | UV stabilized |

| Water Penetration | 24 h |

| Water Penetration Test Method | FOTP-82 | IEC 60794-1 F5 |

Environmental Test Specifications

| Cable Freeze | -2 °C | 28.4 °F |

| Cable Freeze Test Method | FOTP-98 | IEC 60794-1 F15 |

| Drip | 70 °C | 158 °F |

| Drip Test Method | FOTP-81 | IEC 60794-1 E14 |

| Heat Age Test Method | IEC 60794-1 F9 |

| Low High Bend | -20 °C to +60 °C (-4 °F to +140 °F) |

| Low High Bend Test Method | FOTP-37 | IEC 60794-1 E11 |

| Temperature Cycle | -20 °C to +70 °C (-4 °F to +158 °F) |

| Temperature Cycle Test Method | FOTP-3 | IEC 60794-1 F1 |

Packaging and Weights

| Cable weight | 72 kg/km | 48.382 lb/kft |

| Click on image to enlarge. |

Regulatory Compliance/Certifications

| Agency | Classification |

|

CENELEC

|

EN 50575 compliant, Declaration of Performance (DoP) available |

| ISO 9001:2015 | Designed, manufactured and/or distributed under this quality management system |

Documentation & Downloads

Building Information Modeling (BIM) Objects

Declaration of Performance

Product Specification

Warranty

Building Information Modeling (BIM) Objects

Declaration of Performance

Product Compliance Documentation

Product Specification

Warranty

Other Ways to Browse