3499105 | 150T(TD)135WP1250TAPE

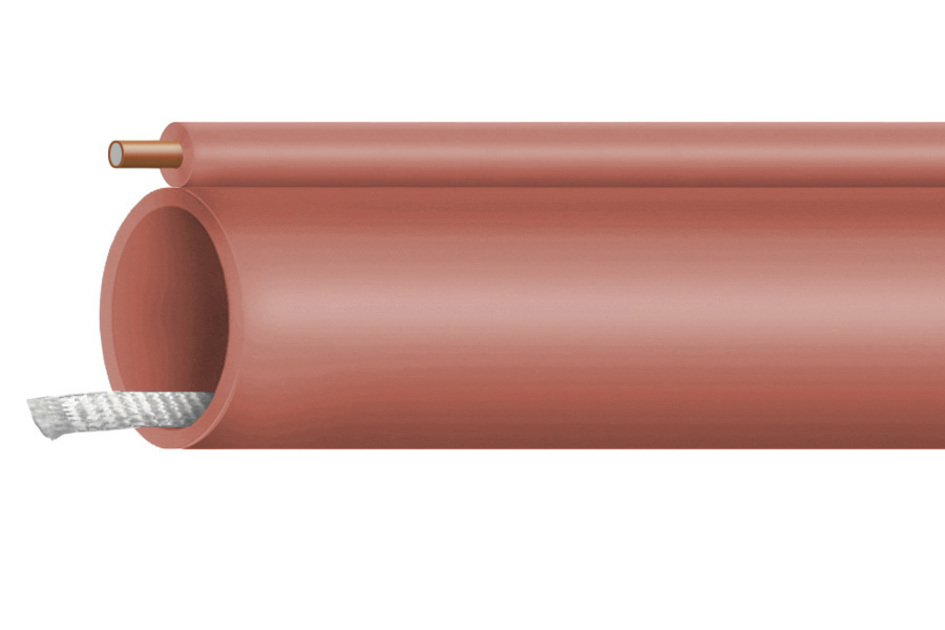

Toneable ConQuest® Empty Conduit, 1 1/2 in, SDR 13.5, terracotta, with pull tape

Specifications

Product Classification

| Product Type | Empty conduit |

| Product Brand | ConQuest® |

General Specifications

| Color | Terracotta |

| Conductor Elongation, maximum | 30 % |

| Conductor Type | Solid |

| Conduit Type | Toneable |

| Density Test Method | ASTM D792A |

| Density, maximum | 0.955 g/cm³ | 0.035 lb/in³ |

| Density, minimum | 0.941 g/cm³ | 0.034 lb/in³ |

| Design Standard | ASTM D3350-05 |

| Wall Type | Smooth |

Dimensions

| Length | 914.4 m | 3000 ft |

| Conductor Diameter | 1.024 mm | 0.0403 in |

| Inner Diameter, nominal | 40.589 mm | 1.598 in |

| Outer Diameter, nominal | 48.26 mm | 1.9 in |

| Wall Thickness Designation | SDR 13.5 |

| Wall Thickness, minimum | 3.581 mm | 0.141 in |

| Nominal Size | 1-1/2 in |

| Conductor Gauge | 18 AWG |

Electrical Specifications

| Conductor Resistance | 98.425 ohms/km | 30 ohms/kft |

Material Specifications

| Conductor Material Type | Copper-clad steel (CCS) |

| Flexural Modulus, minimum | 551.581 N/mm² | 80000 psi |

| Flexural Property Test Method | ASTM D790 |

| Hydrostatic Design Basis | Not pressure rated |

| Hydrostatic Design Test Method | ASTM D2837 |

| Material Type | High density polyethylene (HDPE) | Polyester |

| Melt Flow Rate Test Method | ASTM D1238 |

| Melt Flow Rate, maximum | 0.39 g/10 min |

Mechanical Specifications

| Minimum Bend Radius, unsupported | 508 mm | 20 in |

| Tensile Property Test Method | ASTM D638 |

| Tensile Strength at yield, minimum | 20.684 N/mm² | 3000 psi |

| Breaking Strength | 566.99 kg | 1250 lb |

| Conductor Tensile Strength, minimum | 344.738 N/mm² | 50000 psi |

| Pull Line Type | Tape |

| Pulling Tension Note | Applies to products manufactured after December 31, 2012 |

| Pulling Tension, maximum | 659.977 kg | 1455 lb |

Environmental Specifications

| Environmental Stress Crack Resistance | Failure rate of 10% within 96 hours |

| Environmental Stress Test Method | ASTM D1693, ESCR Condition B |

Packaging and Weights

| Weight, net | 511.928 kg/km | 344 lb/kft |

Regulatory Compliance/Certifications

| Agency | Classification |

| ISO 9001:2015 | Designed, manufactured and/or distributed under this quality management system |

Product Classification

| Product Type | Empty conduit |

| Product Brand | ConQuest® |

General Specifications

| Color | Terracotta |

| Conductor Elongation, maximum | 30 % |

| Conductor Type | Solid |

| Conduit Type | Toneable |

| Density Test Method | ASTM D792A |

| Density, maximum | 0.955 g/cm³ | 0.035 lb/in³ |

| Density, minimum | 0.941 g/cm³ | 0.034 lb/in³ |

| Design Standard | ASTM D3350-05 |

| Wall Type | Smooth |

Dimensions

| Length | 914.4 m | 3000 ft |

| Conductor Diameter | 1.024 mm | 0.0403 in |

| Inner Diameter, nominal | 40.589 mm | 1.598 in |

| Outer Diameter, nominal | 48.26 mm | 1.9 in |

| Wall Thickness Designation | SDR 13.5 |

| Wall Thickness, minimum | 3.581 mm | 0.141 in |

| Nominal Size | 1-1/2 in |

| Conductor Gauge | 18 AWG |

Electrical Specifications

| Conductor Resistance | 98.425 ohms/km | 30 ohms/kft |

Material Specifications

| Conductor Material Type | Copper-clad steel (CCS) |

| Flexural Modulus, minimum | 551.581 N/mm² | 80000 psi |

| Flexural Property Test Method | ASTM D790 |

| Hydrostatic Design Basis | Not pressure rated |

| Hydrostatic Design Test Method | ASTM D2837 |

| Material Type | High density polyethylene (HDPE) | Polyester |

| Melt Flow Rate Test Method | ASTM D1238 |

| Melt Flow Rate, maximum | 0.39 g/10 min |

Mechanical Specifications

| Minimum Bend Radius, unsupported | 508 mm | 20 in |

| Tensile Property Test Method | ASTM D638 |

| Tensile Strength at yield, minimum | 20.684 N/mm² | 3000 psi |

| Breaking Strength | 566.99 kg | 1250 lb |

| Conductor Tensile Strength, minimum | 344.738 N/mm² | 50000 psi |

| Pull Line Type | Tape |

| Pulling Tension Note | Applies to products manufactured after December 31, 2012 |

| Pulling Tension, maximum | 659.977 kg | 1455 lb |

Environmental Specifications

| Environmental Stress Crack Resistance | Failure rate of 10% within 96 hours |

| Environmental Stress Test Method | ASTM D1693, ESCR Condition B |

Packaging and Weights

| Weight, net | 511.928 kg/km | 344 lb/kft |

Regulatory Compliance/Certifications

| Agency | Classification |

| ISO 9001:2015 | Designed, manufactured and/or distributed under this quality management system |

Documentation & Downloads

Installation Instruction

Product Specification

Warranty

Installation Instruction

Product Compliance Documentation

Product Specification

Warranty

Other Ways to Browse